KESSLER SOILS ENGINEERING

KSE Testing Equipment (KSE), a Kessler Soils Engineering Products, Inc. company, is located in Northern Virginia near Dulles International Airport. In 2019, we are celebrating our 25th Anniversary. KSE is a unique organization that not only manufactures and distributes testing equipment for highway and airfield construction but also provides services to our customers that includes on-site technical support and training by our Engineering staff.

The company started in 1994 manufacturing Dynamic Cone Penetrometers (DCP) under license from the U.S. Government using the US Army Corps of Engineers patented design. This design is required to meet ASTM D6951. We have grown and diversified by adding new products like the DCP Magnetic Ruler Data Collection Device which allows single person operation of the DCP because it automatically records the data and calculates the California Bearing Ratio (CBR) value and ultimate bearing strength. KSE has been the sole provider of Soils Test Sets for the US Marine Corps and US Army in the last 15 years.

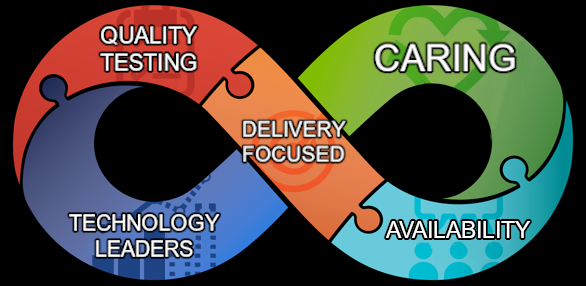

KSE Core Values

- Delivery Focused making sure that our products arrive in time to support our customers’ needs, anywhere in the world

- Quality Testing Devices that provide accurate, repeatable & meaningful results

- Available to Support customers using any of our products

- Technology Leaders bringing to the U.S. market leading technologies that help construct quality & lasting highways & airfields

- Caring for People who are our customers, employees, vendors, partners and community helping each other when they have a need

KSE Objectives

- Providing Quality Products at a fair price

- Support our customers & partners with strong technical service including repairs, calibrations, training & spare parts

- Deliver superior services and products that motivate our customers for repeat business

- Grow the business by providing unique products & services to our government and commercial customers

- Maintain close cooperation with the companies whose products we distribute; working as partners

Customer Satisfaction

Customer satisfaction is of primary importance to our organization. KSE has engineers on call to assist users in understanding how each piece of equipment works. We provide on-site training for any of our products. In addition, our sales personnel and friendly office staff will help in any way they can to ensure customer satisfaction. We are proud of our follow up with and from our customers. This feedback from the field has led to manufacturing refinements and improvements in techniques that we share with other customers and is incorporated into future instrument design and user manual updates.

Distributor for Zorn Light Weight Deflectometer (LWD)

In 2003, KSE became the sole distributor in the United States for the Zorn Light Weight Deflectometer (LWD) which meets ASTM E2835. The LWD measures deflection and calculates modulus of the soil. KSE is certified by Zorn to perform LWD Calibrations and repairs thus avoiding the cost and time to ship the devices to Germany. In 2013, KSE successfully introduced to the Zorn Asphalt LWD device for testing new Hot Mix Asphalt pavements and evaluating existing pavements. We have the only calibration stand in North America, once the unit clears customs it never has to go back to Germany.

Sole distributor for the MIT Magnetic Tomography NDT equipment

In 2009, KSE moved into pavements and became the sole distributor for the MIT Magnetic Tomography NDT equipment that evaluates concrete pavement dowel bar installation and pavement thickness. KSE provides on-site training, repair services and stocks spare parts for the Zorn & MIT product lines.

Distributor for Hydramotion Micro-Lance

In 2013, we became distributors for the Hydramotion Micro-Lance, the instrument measures moisture and temperature of minerals and building materials at depths up to six feet (nearly 2 meters) – simply by insertion. The digital readings are shown instantly. The MicroLance has a built-in computer which gives it the flexibility to handle a wide range of materials and water contents.

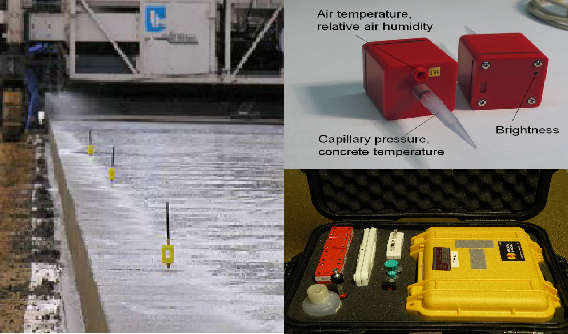

Distributor for the Capillary Pressure Sensor System

The Research and Transfer Center at the Leipzig University of Applied Sciences in Germany developed a Capillary Pressure Sensor System (CPSS) for the on-site measurement of the capillary pressure in plastic concrete, i.e., during the first few hours after casting. On the basis of the measurement results, it is possible to evaluate the cracking risk, to estimate the demand for curing measures, and to prove the efficiency of the same.